Sand Trap/KnockOut

The need for solids removal before initial separation has grown with the increase of hydraulic fracturing across U.S. shale basins. RBI Sand Traps and Knockouts protect customer investments in production and processing equipment by reducing the damaging effects of solids on piping and vessels. RBI offers two types of sand traps/knockout separation equipment, the Striker Plate and Cyclonic.

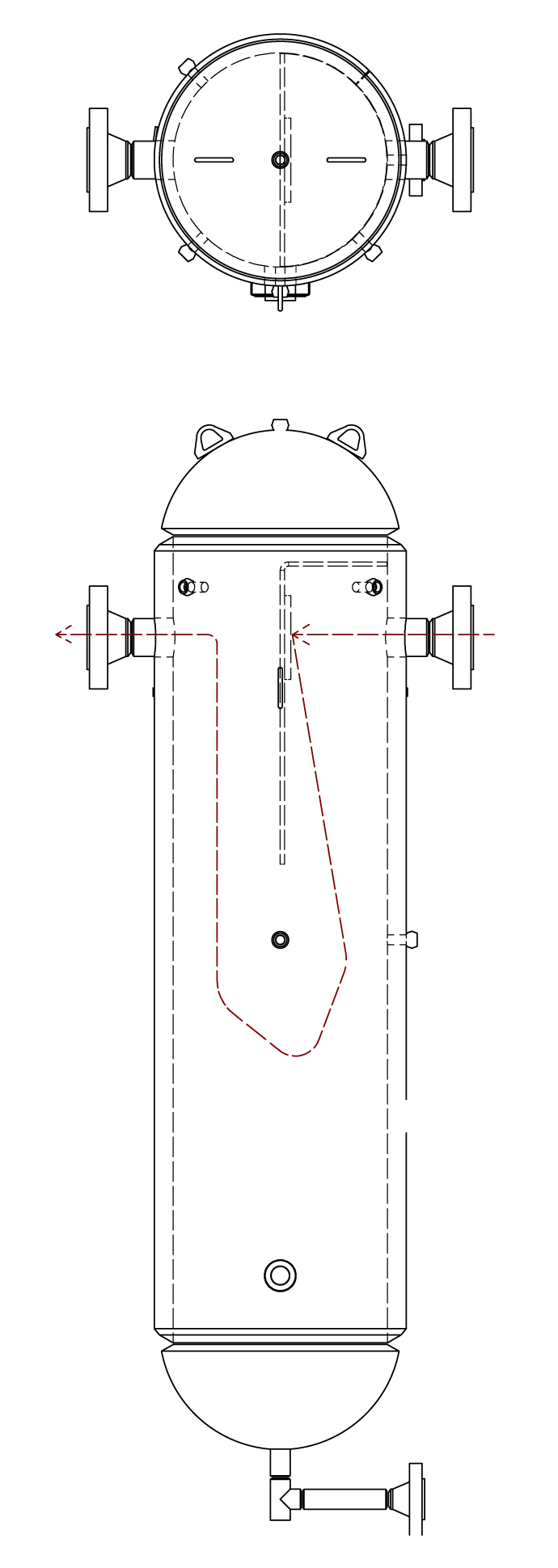

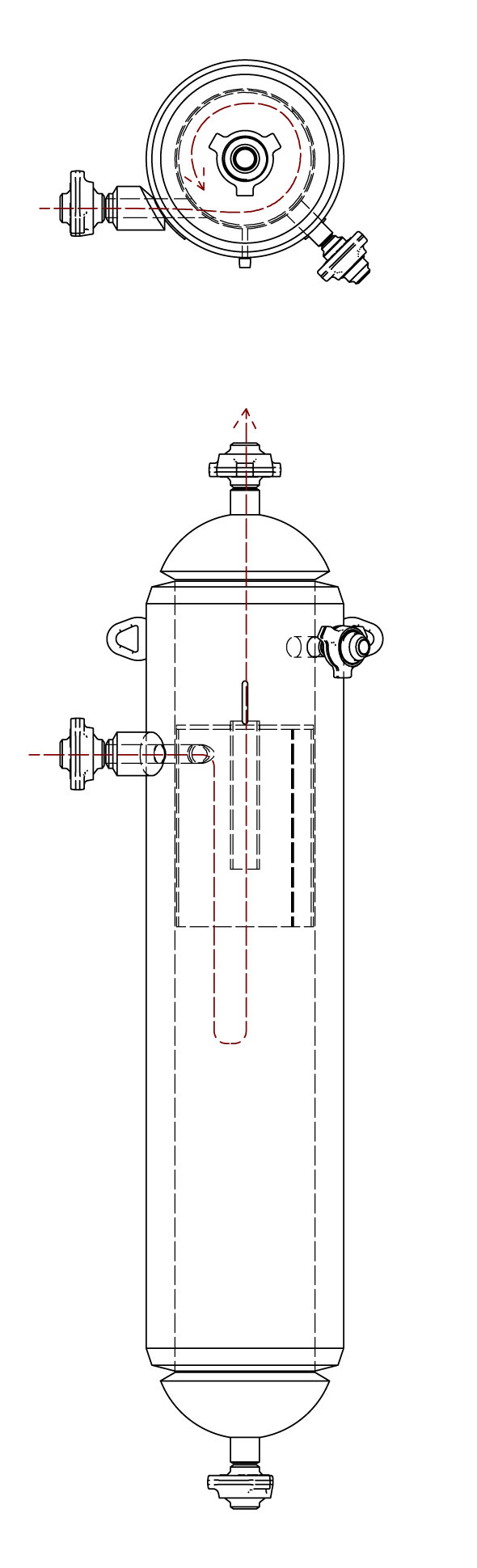

The Striker Plate Sand Separator is a gravity sand trap with a reinforced striker plate installed at the point where the produced fluid first enters the trap. The Striker Plate is designed to absorb the impact of the incoming flow, particularly the sand particles, and help prevent damage to the vessel’s internal components from repeated strikes.

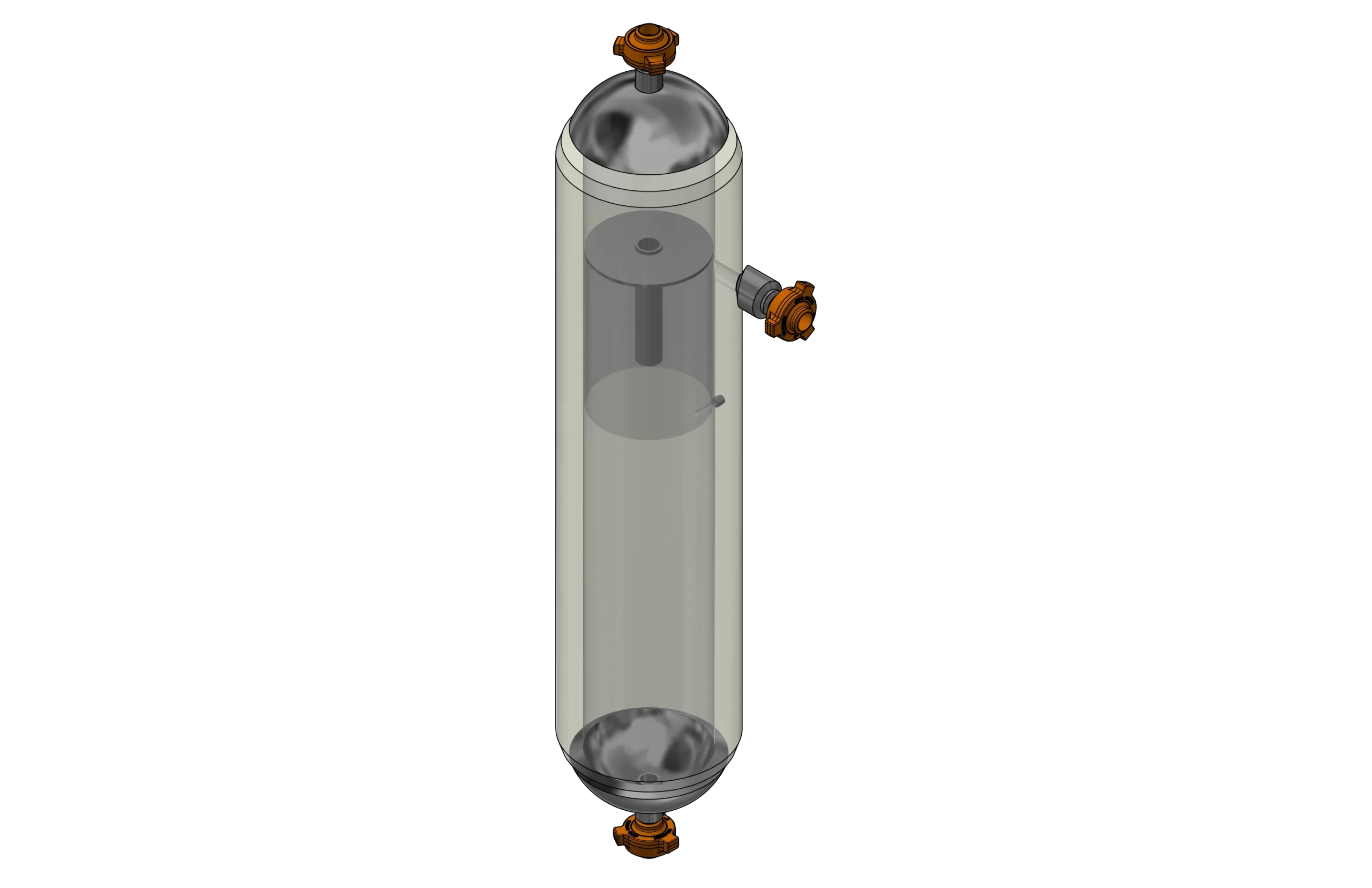

The Cyclonic Sand Trap is a pressurized vessel used to separate sand from liquid. This unit can also be used for the flow back of effluent-containing proppant following fracture treatment.

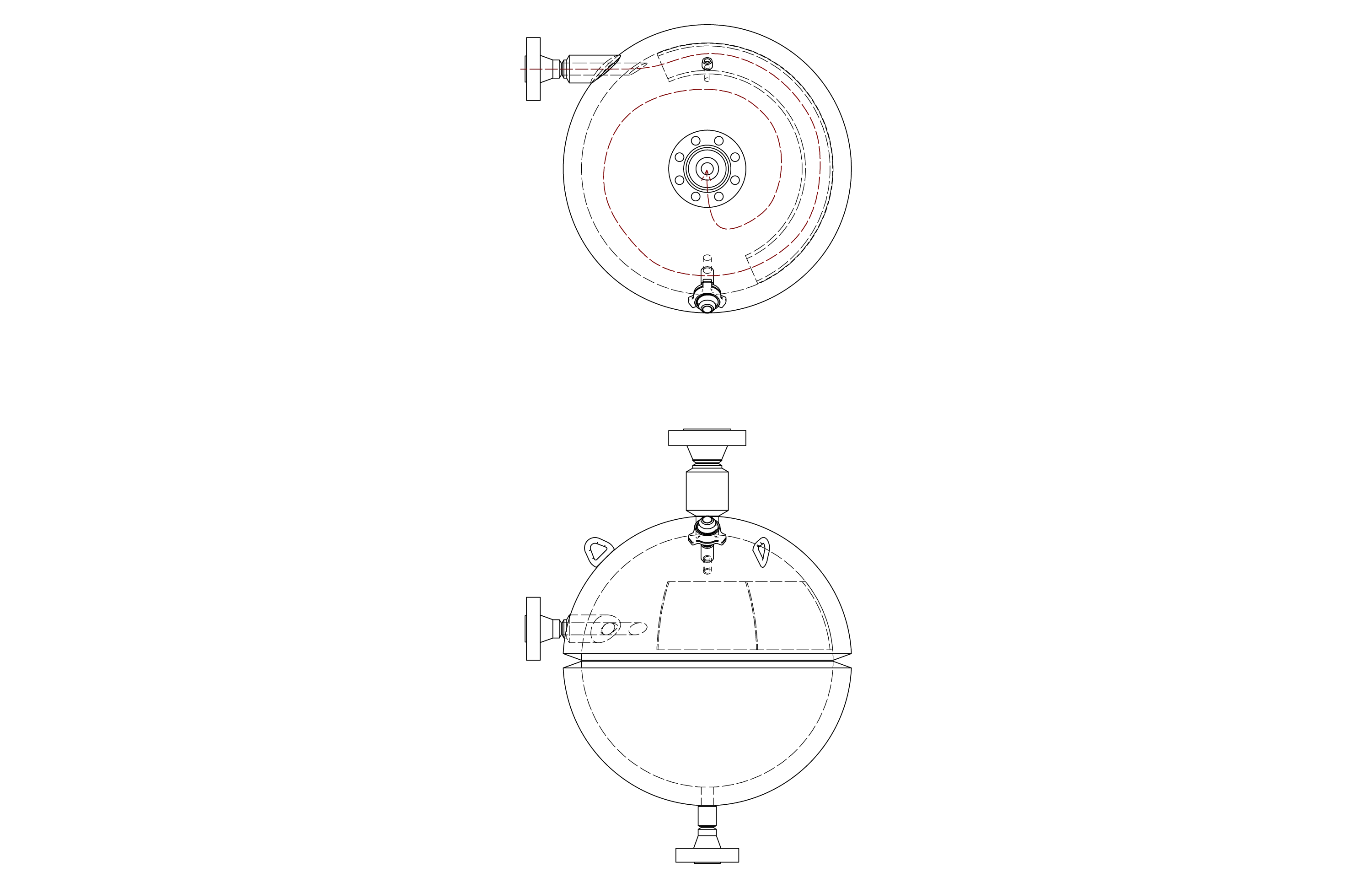

A Spherical Sand Trap or Sand Separator is a vessel designed to separate sand and other heavy solids from well fluids. Unlike standard sand traps, it does not use a cylindrical shell. Instead, its spherical design provides a user-friendly and accessible approach while also increasing gas capacity.

Specifications

Vertical Striker Plate / Vertical Cyclonic

Size Range: 12″ to 60″

Skid: Built to AWS D1.1 Specifications

Certification: Built to ASME Section VIII, Div 1 or 2 and National Board Registered

Specifications

Spherical Sand Trap / Sand Separator

Built To ASME Section VIII, Div 1 or 2 and National Board Registered

Size Range:

60-in. ID x 3,000 – 10,000 PSI

48-in. ID × 3,000 – 10,000 PSI

36-in. ID × 3,000 – 10,000 PSI

Piping Per Customer Specifications

Pressure relief valve Per Customer Specifications

Applications

Drilling

FlowBack

Production