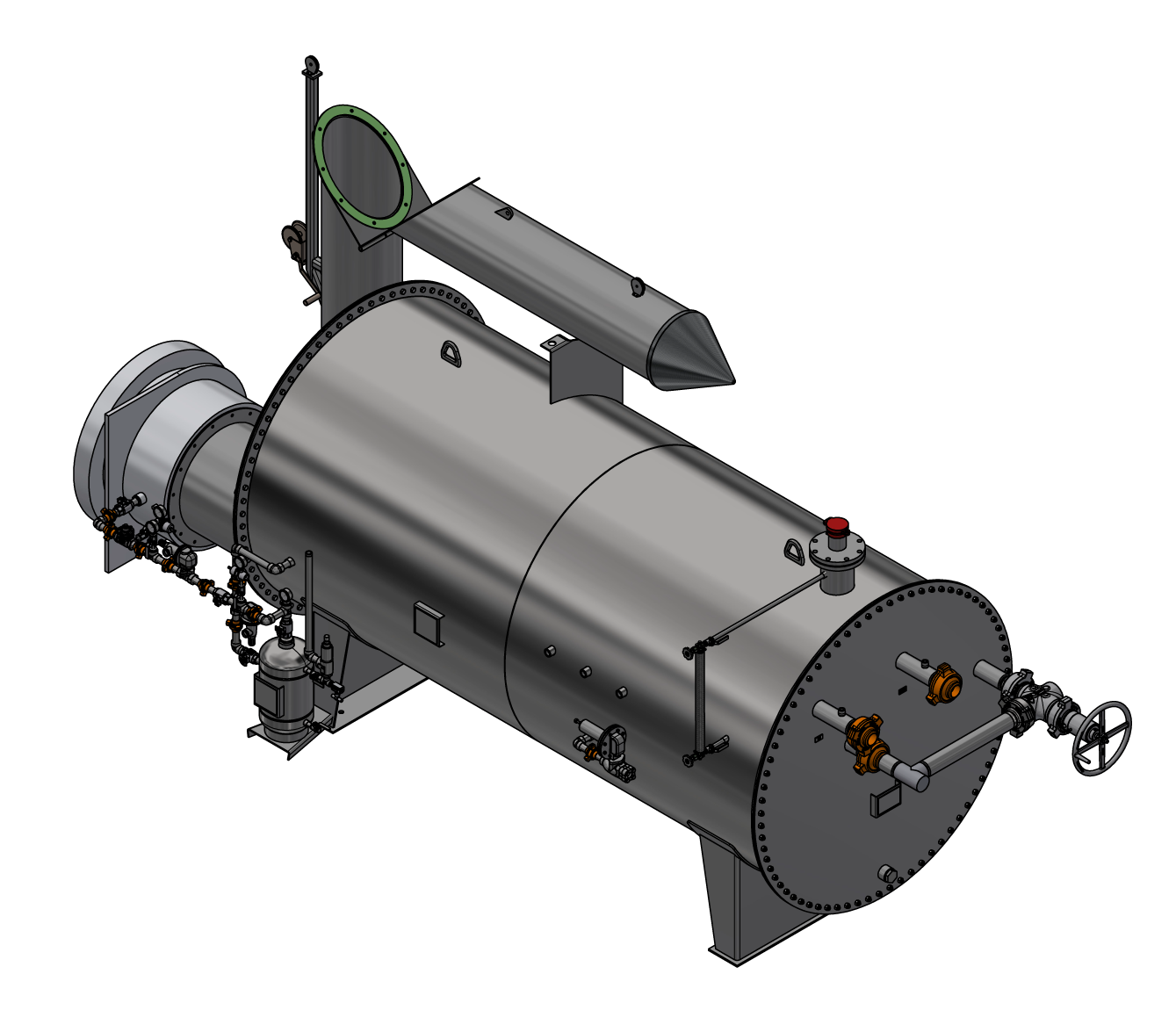

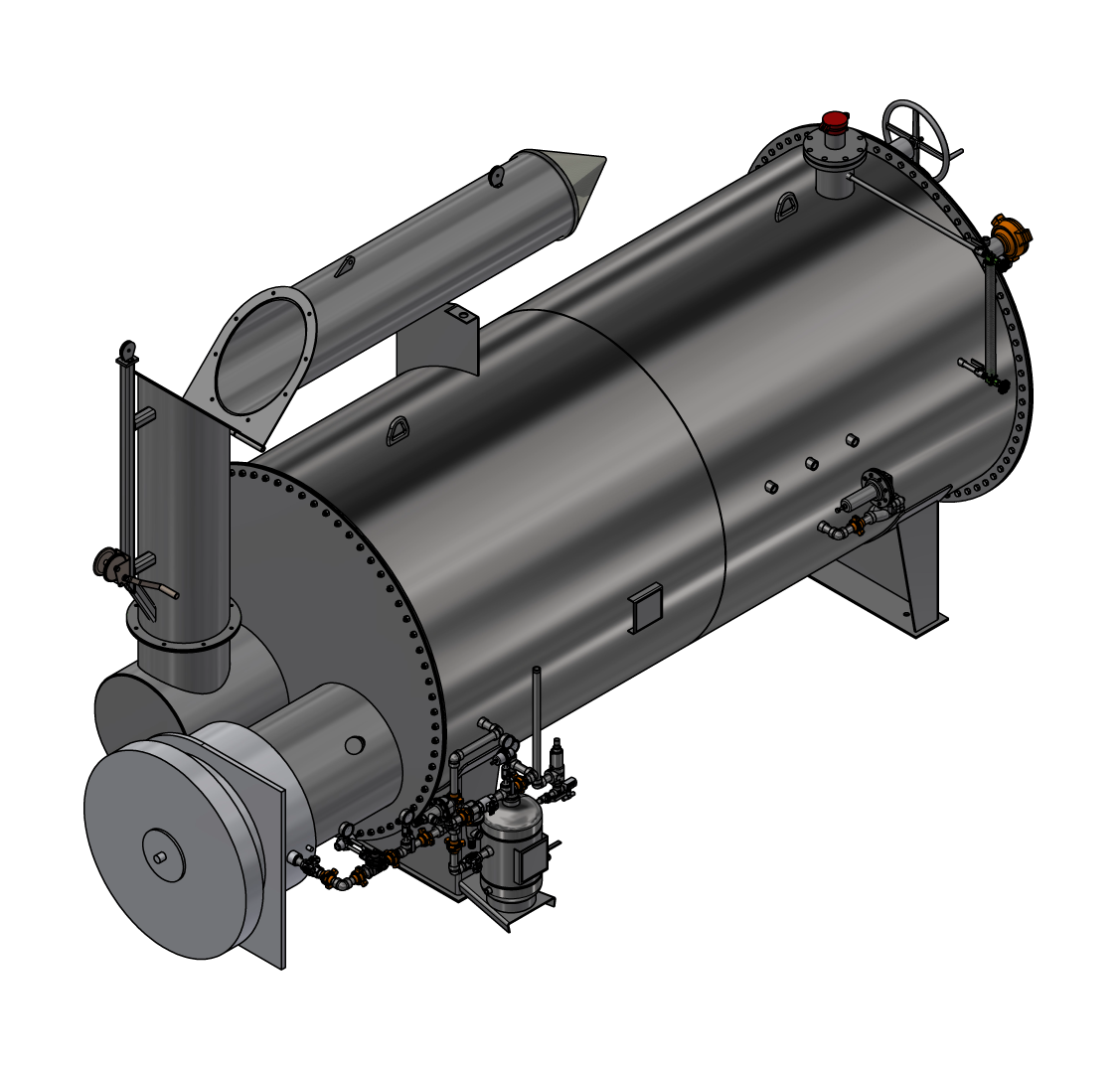

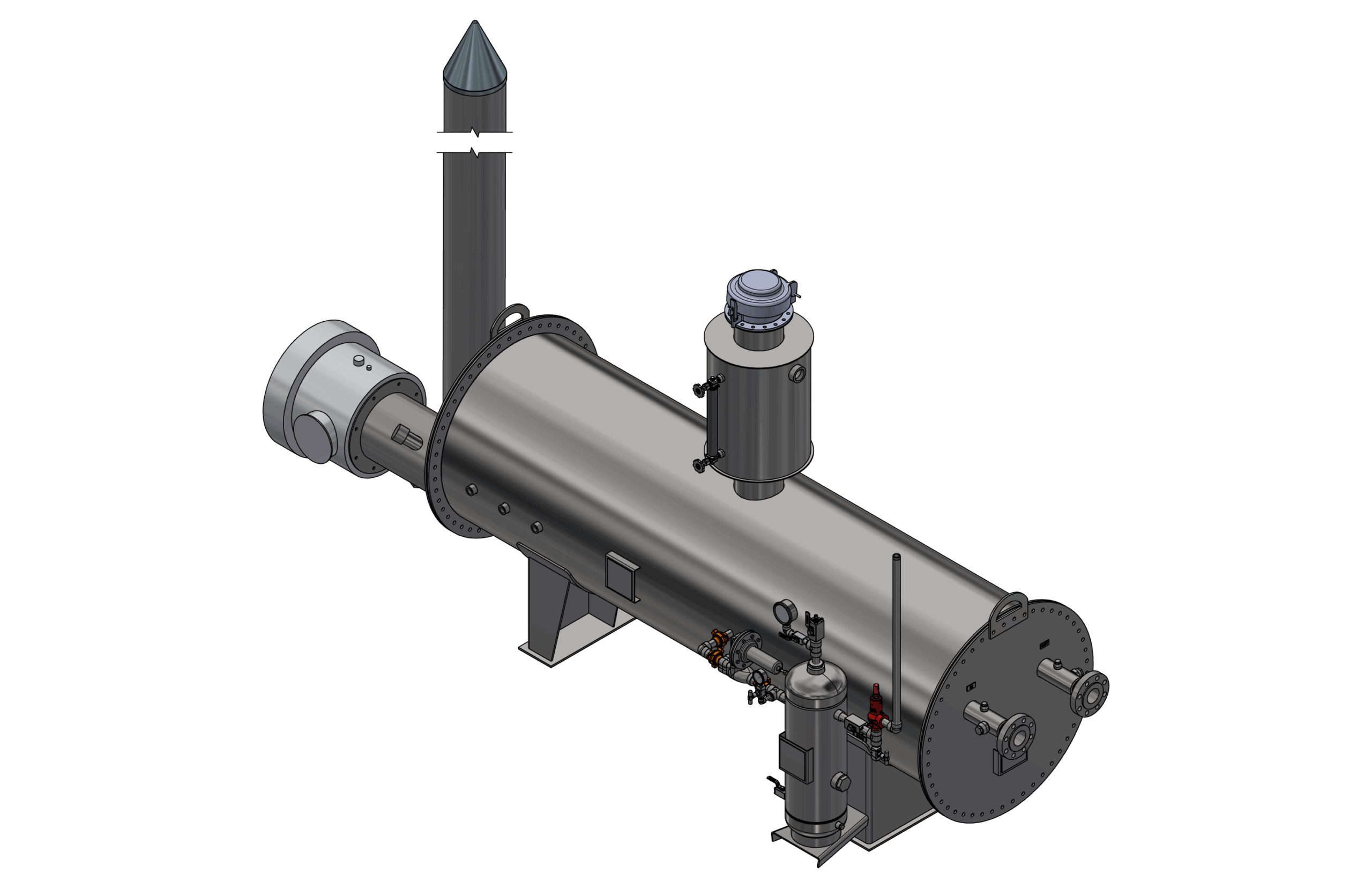

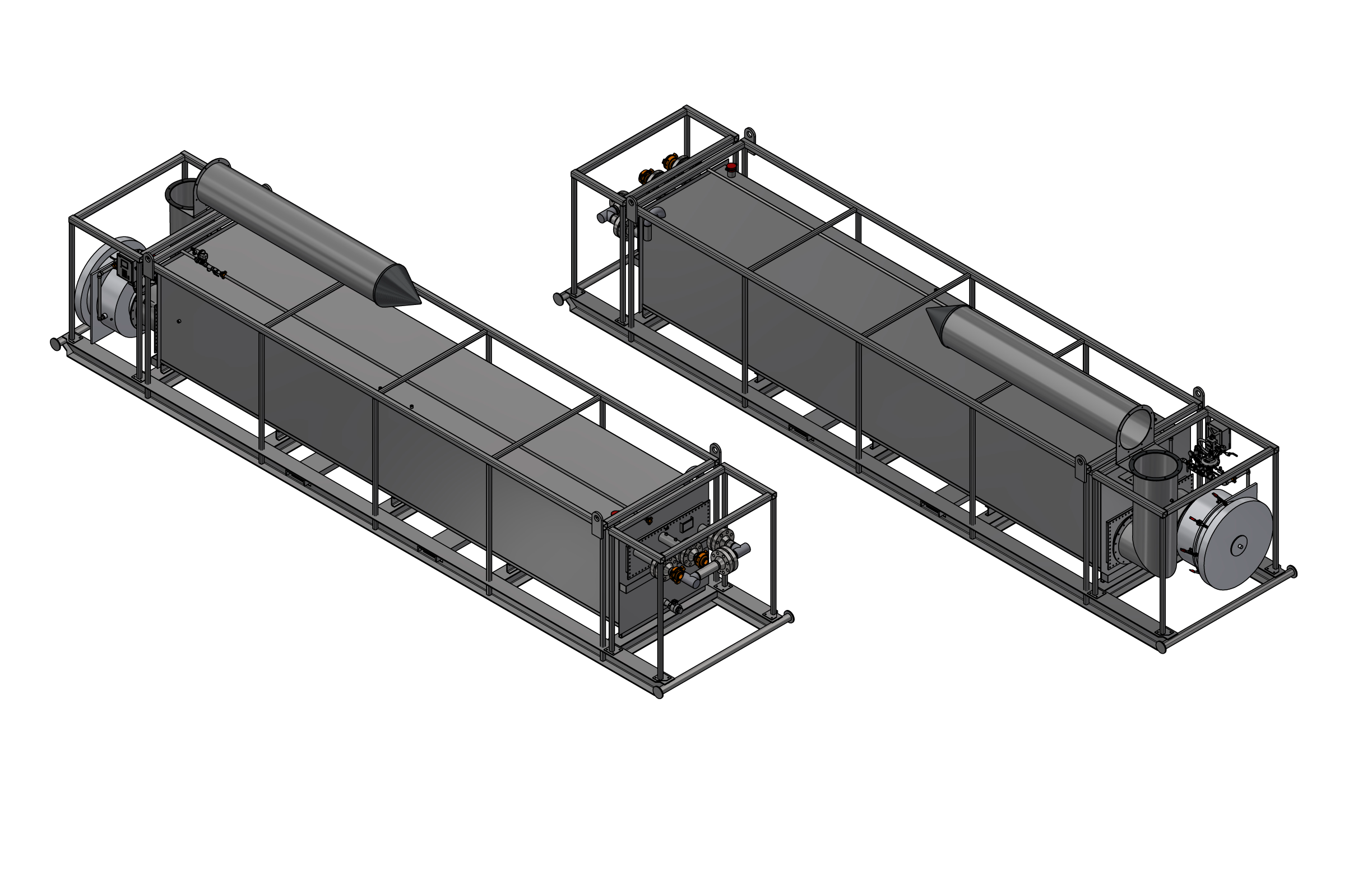

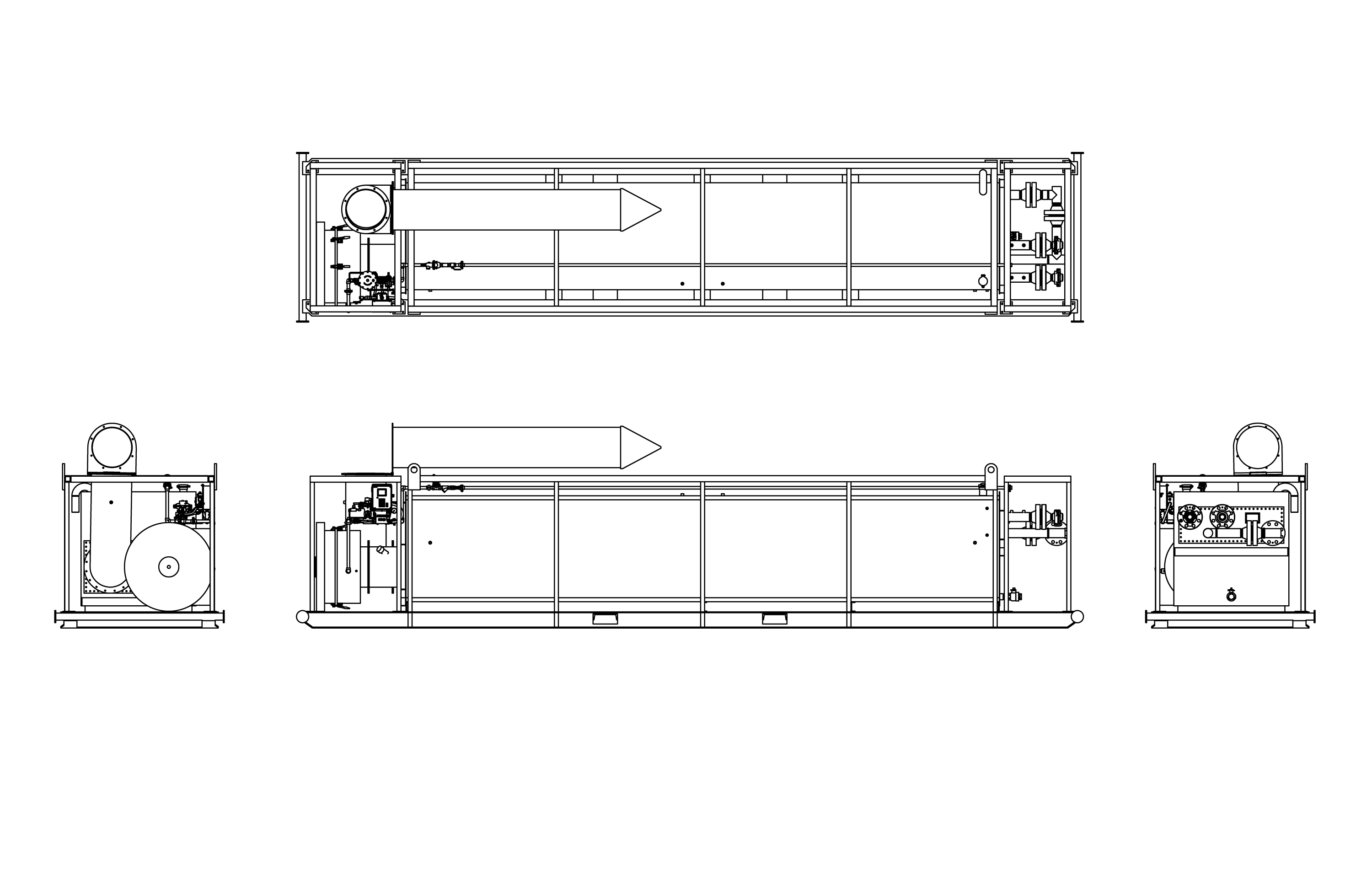

INDIRECT LINE HEATERS

Address pressure drops and hydrate formation with RBI’s Indirect Line Heaters. Often referred to as coiled heaters, indirect line heaters are designed to maintain optimal process temperatures and prevent hydrate-related obstructions in oil and gas systems including freezing in lines, valves and separators. They use a firetube submerged in a glycol medium that transfers heat to a coil. Using heat to stabilize temperatures before and after pressure drops, line heaters ensure safe, continuous and efficient production. RBI’s line heaters reduce pressure at the choke—upwards of 2,000 PSI—to match the downstream separator’s maximum allowable working pressure.

Specifications

and features

Size Range:

75,000 BTU/HR to 4MMBTU/HR

Firetube and coil designed for various applications and are removable and non-removable

High and Low Pressure Coils – Designed with and without a pressure reducing choke

Coil Pressure Rating:

50 PSI – 10,000 PSI

Round and square designs for different applications

I&E and BMS systems optioned

Applications

MIDSTREAM

Production